Struggling to select the right power strips? The wrong choice can limit sales and harm your brand image.

The right power strip depends on features, certifications, and design compatibility with your target market.

I will guide you step by step so you can avoid costly mistakes.

Why is power strip selection important for your product line?

Choosing the wrong model creates safety risks, lost sales, and wasted investment.

Power strips affect safety, performance, and customer trust in your product line.

Why safety certifications matter?

If a power strip lacks ETL or cETL approval, many retailers reject it. Customers today also check labels carefully. When certifications are missing, they lose confidence. I learned this early when a buyer returned to me with concerns. I had to replace an entire order at my own cost.

How to evaluate safety standards?

| Certification | Region | Importance |

|---|---|---|

| ETL & cETL | US & Canada | Required by major retailers |

| CE | Europe | Shows compliance with EU standards |

| ISO 9001 | Global | Demonstrates reliable factory process |

The smart decision is always to check if the supplier holds updated certifications. Old or expired documents can cause shipment delays. I had a case where a client’s peak sales season was delayed because a competitor supplier gave them an outdated ETL file. That mistake cost them shelf space at a big-box retailer.

Why do buyers insist on certified suppliers?

Procurement officers want to reduce risk. If a product fails in the field, the brand suffers. Certification provides proof that the power strip has passed testing. It also saves time in customs clearance and protects against liability. The upfront cost of compliance is smaller than the loss from product recalls.

What features should you look for in power strips?

Many buyers think only about outlet count. But features define how competitive the product becomes.

Smart features, USB charging, and surge protection increase product appeal in B2B markets.

Key product features that matter

| Feature | Why it matters | Example |

|---|---|---|

| Surge protection | Protects electronics | 1200J, 2450J models |

| USB ports | Reduces need for chargers | PD 20W or PD 35W |

| Housing material | Safety and design | ABS or metal casing |

| Spacing of outlets | Fits large plugs | Wide-spaced design |

Why does surge protection define value?

In my experience, surge protection is not just a technical detail. Buyers use it as a marketing term. One client in Canada requested 1200J models because their distributor demanded higher levels. When I offered 2450J with LED indicators, the product became their bestseller. Surge protection can be the difference between a commodity product and a premium SKU.

USB ports and charging demand

Customers now charge multiple devices at once. A power strip without USB is outdated. PD 35W Type-C ports allow charging of laptops like MacBook Air. Buyers in North America see this as a selling point. It is also easier to market online because specifications are clear and attractive.

Design and material influence perception

Plastic feels standard. Metal feels premium. Some of our retro-style power strips in metal housings sell faster because they match modern kitchens. Buyers from lifestyle retailers often request these because they fit home décor trends.

How to balance cost and quality?

Low prices win orders, but poor quality destroys trust.

Balancing cost and quality ensures stable sales and protects your long-term brand.

Why procurement officers push for cost control

I have spoken with many buyers like Steve. They always ask for competitive pricing. They want to maintain margins. But when I show them how poor material shortens product life, they often agree to upgrade. A failed batch costs more than a slightly higher purchase price.

Practical cost vs. quality comparison

| Factor | Low-cost option | Balanced option |

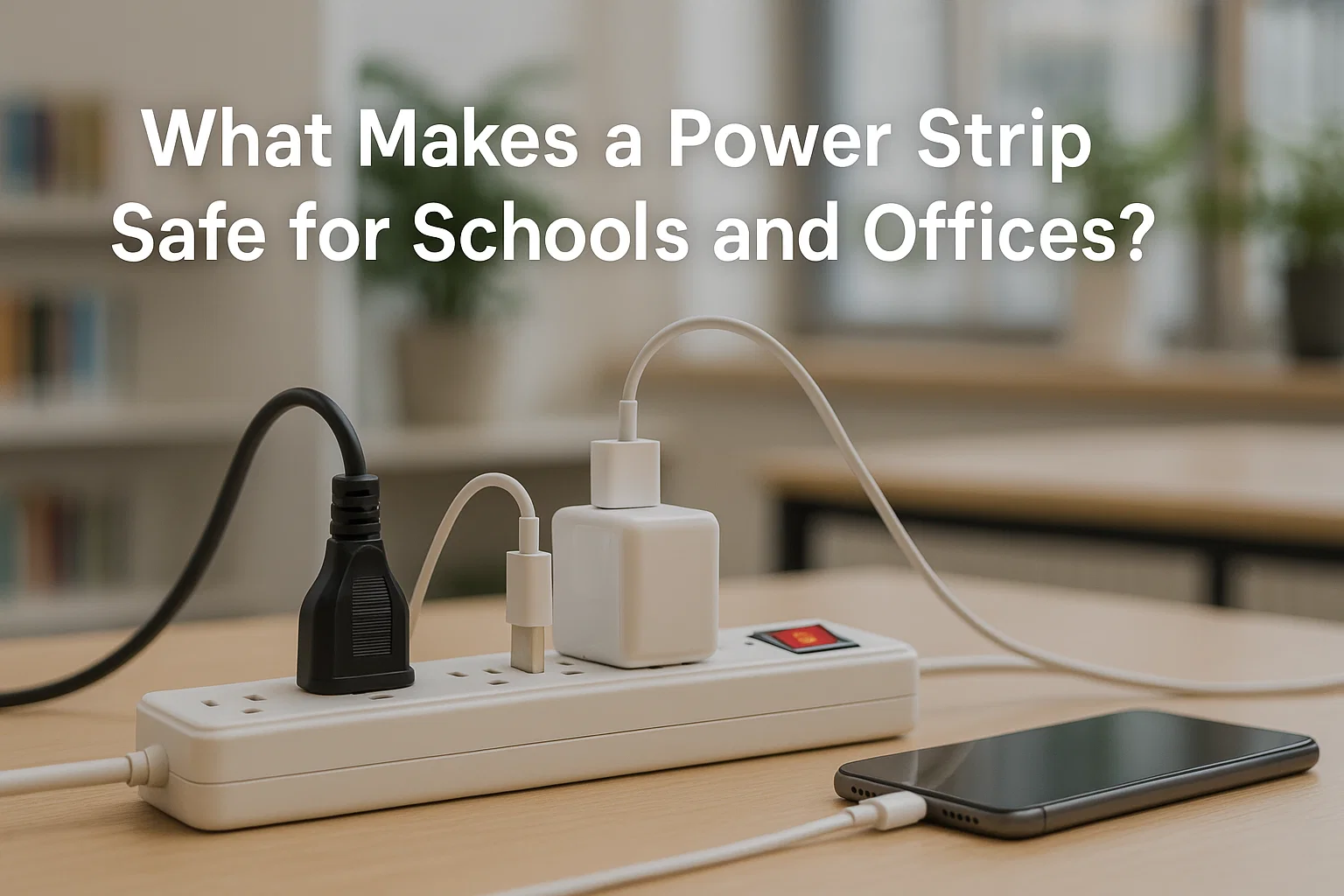

|---|---|---|

| Cable | Thin, overheats | SJT 14AWG heavy-duty |

| Plug | Standard | Flat plug, easy use |

| USB | Slow charging | Fast PD charging |

| Housing | Fragile ABS | Durable ABS or metal |

How buyers can decide smartly

I advise procurement officers to think about long-term savings. A balanced model reduces warranty claims. It keeps customers loyal. It also avoids brand damage. Buyers should compare specifications side by side. When presented in tables, the difference becomes clear.

My own experience with cost-quality tradeoff

Years ago, I supplied a low-cost batch for a new customer. They wanted the cheapest model. Within six months, they faced returns. The retailer dropped them. I learned never to recommend the lowest tier when brand reputation is at stake. Now I always propose balanced models with proven durability.

How to choose the right supplier?

A strong product line needs a reliable partner.

The right supplier offers certifications, stable lead times, and professional communication.

What buyers must evaluate in suppliers

| Supplier factor | Why it matters |

|---|---|

| Factory audits | Prove capacity and compliance |

| Certifications | Show quality and safety |

| Lead time | Determines market entry speed |

| MOQ flexibility | Matches your launch strategy |

| Communication | Prevents costly misunderstandings |

Why audits matter

Some suppliers claim experience but lack structure. A proper SCAN or BSCI audit proves they follow process. ISO 9001 certification confirms their quality system. Without these, production can face hidden risks. I worked with a buyer who lost an order window because their previous supplier could not scale up. With my audited partner factory, we delivered on time.

The role of communication

Many buyers complain about poor response times. Delays in email replies mean lost opportunities. I make sure my communication is fast and clear. I know procurement officers like Steve do not want to chase information. Reliable communication builds trust and shortens the decision cycle.

Delivery and payment terms

Buyers look for predictable delivery. Our lead time is 45–50 days, which fits most retail schedules. Payment terms with T/T are clear and simple. Many procurement officers prefer this because it reduces complexity compared to letters of credit.

Conclusion

Choosing the right power strip requires balancing safety, features, cost, and supplier reliability.