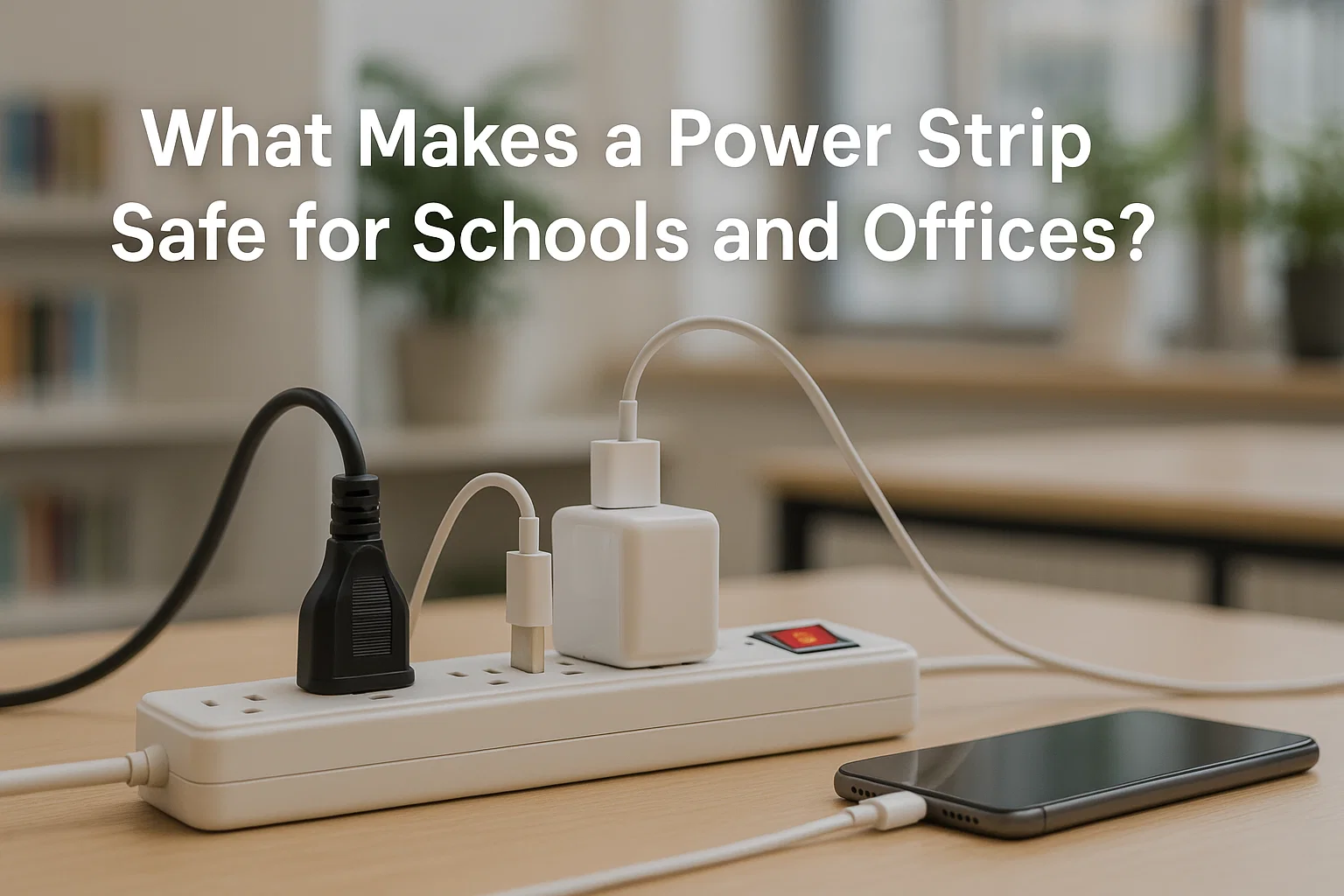

A power strip is simple—but packed with critical components.

A power strip includes outlets, internal wiring, safety features, and housing, all working together to distribute electricity.

Many buyers only see the surface. Let's look inside and understand what matters most.

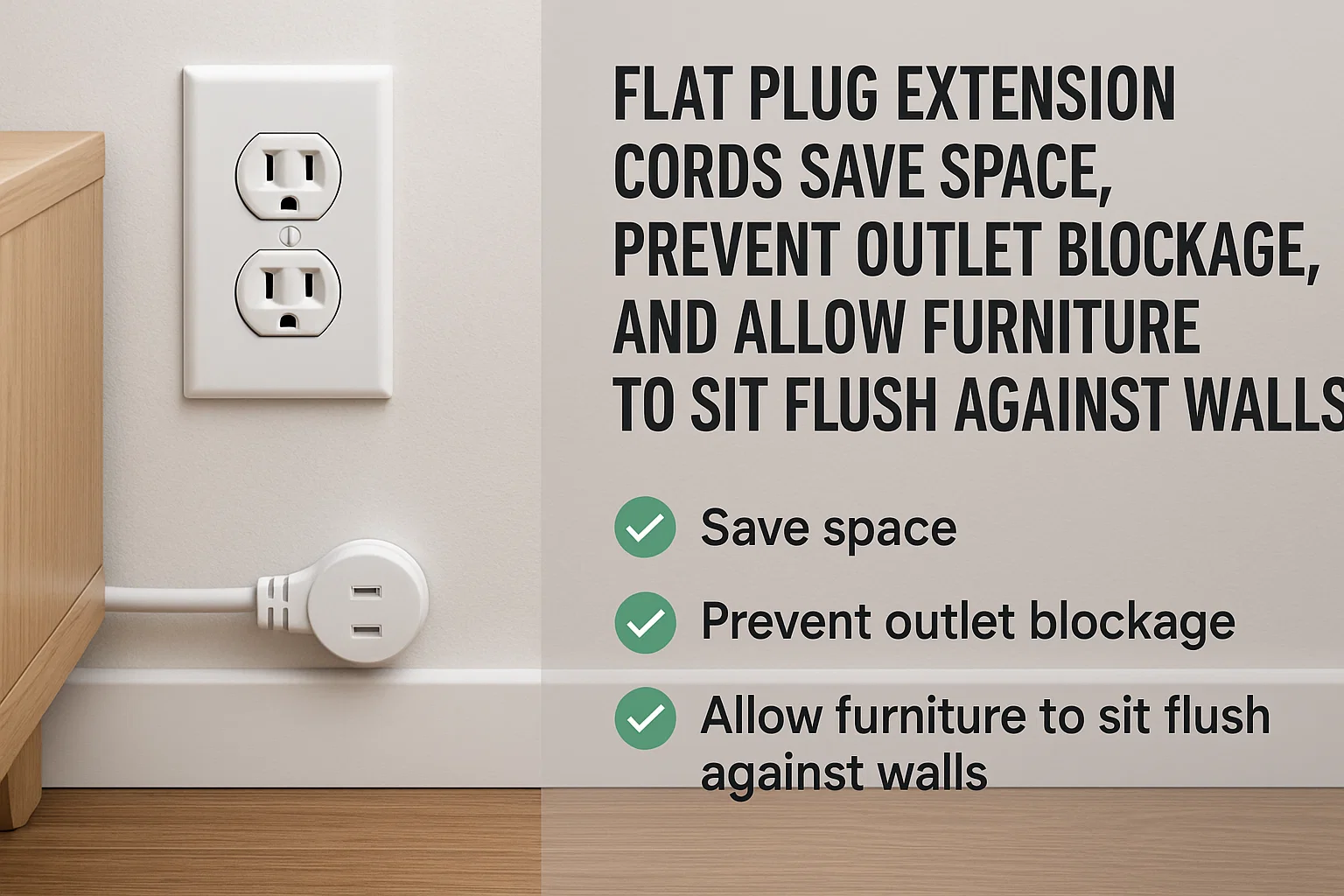

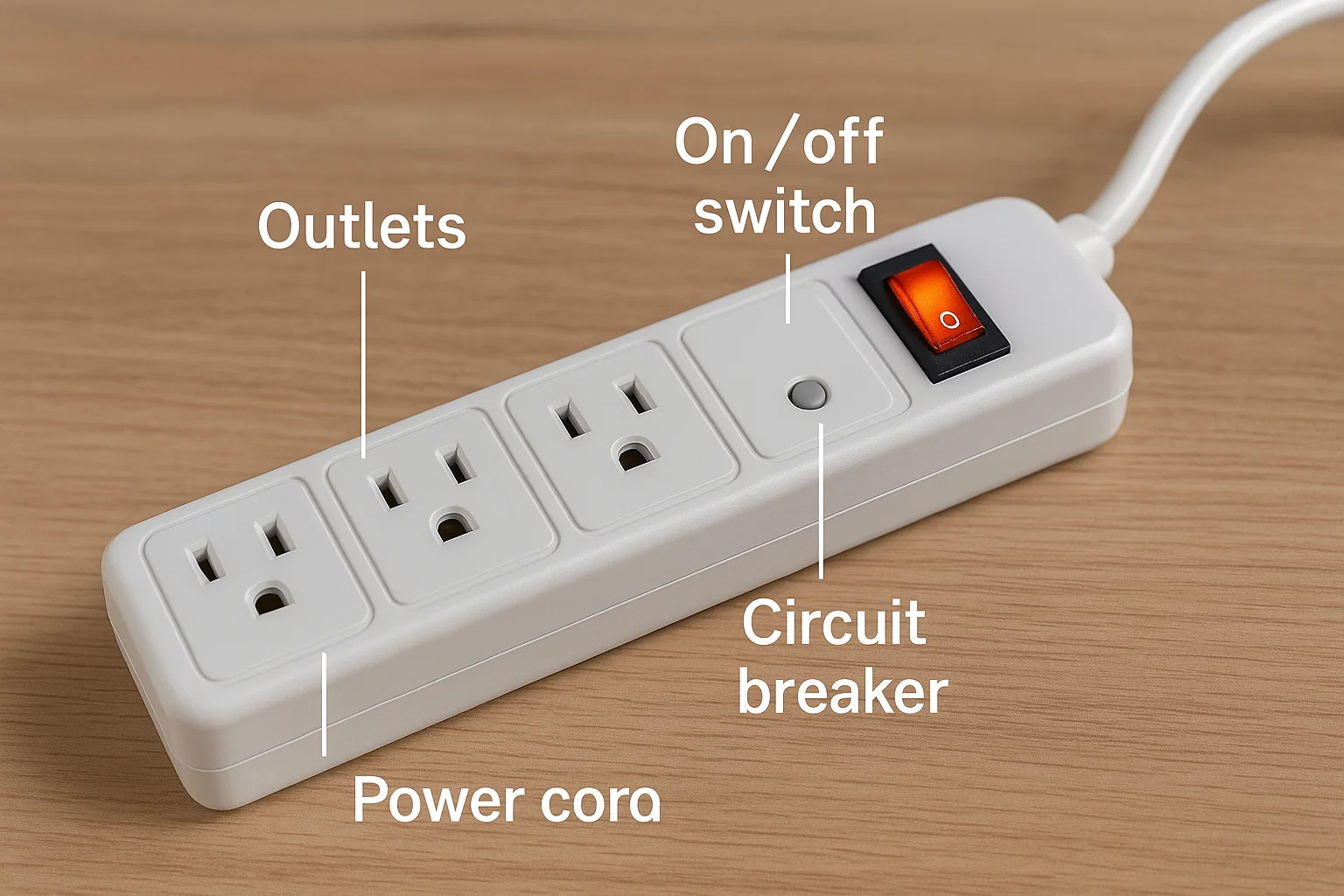

What are the external components of a power strip?

The outside is where users interact—but design impacts safety.

The housing, plug, cord, and switch are key external parts that affect usability and durability.

A Closer Look at the Exterior

These external parts must handle daily wear and tear. For buyers like Steve, knowing the material and certification status of these parts is essential for selecting quality.

| Part | Function | Material Choices |

|---|---|---|

| Housing | Encases all internal parts | ABS, PC, or metal |

| AC Outlets | Allow users to plug in devices | Brass or phosphor bronze |

| Power Cord | Delivers electricity from the wall | PVC-coated copper |

| Plug | Connects to wall socket | Molded with copper pins |

| On/Off Switch | Controls power flow to all outlets | Lighted rocker or reset |

| Mounting Slots | Allow installation on walls or desks | Molded into backplate |

External parts are where users feel quality first. Cheap plastics can crack. Weak cords get hot. Our Wakeup power strips use thick copper wiring and flame-retardant ABS housings—because that’s what our retail customers demand.

What are the internal components of a power strip?

Inside the casing is where real safety happens.

The internal wiring, PCB, and surge modules manage electricity flow and protect connected devices.

What’s Hidden Inside?

A typical power strip contains multiple layers of protection, routing, and grounding. Smart designs also include components that regulate power delivery.

| Component | Role |

|---|---|

| Copper Bus Bars | Distribute current evenly to all outlets |

| Internal Wiring | Connects outlets, switch, and plug |

| MOVs | Absorb voltage surges |

| Fuse/Circuit Breaker | Protects from overload or short circuits |

| PCB (if USB) | Controls voltage for USB charging ports |

| Ground Connection | Ensures fault current is safely directed away |

Real-Life Product Examples

In our factory, we test every single internal connection. We often get clients who've received power strips with fake surge protection. Some factories even skip the MOV entirely! That’s a disaster waiting to happen. That’s why we open up samples and document every part—especially for ETL audits.

What materials are used inside power strips?

Material selection changes everything—from lifespan to certification.

The choice of copper, plastic, and protection components determines durability, cost, and safety.

Don’t Judge by the Cover

Inside the best power strips, you’ll find high-conductivity copper, industrial-grade thermoplastics, and certified surge components. The wrong materials can cause overheating, melting, or fire.

| Material | Common Grade Used | Better Grade Alternative | Why It Matters |

|---|---|---|---|

| Copper wire | CCA (copper-clad) | Pure copper | CCA breaks or overheats |

| Plastic housing | Recycled ABS | Virgin flame-retardant PC | Melts under overload |

| MOV surge module | Low joule rating | 1200–2450J certified MOV | Fails during real surges |

We always use pure copper for internal wiring and bus bars—even if it adds a few cents. And we document the origin and rating of every MOV, especially for our North American customers.

How do USB ports work inside a power strip?

Modern power strips are more than outlets—they charge your life.

USB ports contain smart chips, step-down circuits, and thermal protection, enabling safe fast charging.

The Tech Behind the USB

Power strips with USB need more than wiring—they use microchips and power regulation ICs. These components convert 110V/220V AC into 5V DC, often with PD (Power Delivery) or QC (Quick Charge) support.

| USB Feature | Function |

|---|---|

| Smart IC | Detects device type and adjusts power output |

| Step-down converter | Converts AC to regulated DC power |

| PD/QC chip | Enables fast charging at 18W–35W |

| Thermal sensor | Shuts off USB if temperatures rise |

USB ports are often where compliance fails. We always ensure our USB chargers pass load testing and are certified for PD/QC compatibility. Especially for business buyers, a failed USB port means returns, reviews, and reputation damage.

What safety features are built into a power strip?

Safety is not optional—it’s expected.

Key safety parts include surge protectors, resettable circuit breakers, grounding, and flame-retardant housing.

How Protection is Layered

Good power strips protect in multiple ways—not just with fuses. They monitor heat, detect overload, and stop fire risks before they start.

| Safety Feature | Function |

|---|---|

| Circuit Breaker | Cuts power when current exceeds rating |

| Surge Protection | Absorbs voltage spikes |

| Grounding | Prevents electric shock |

| Flame-Retardant Shell | Slows combustion if internal failure occurs |

In our factory, we apply SCAN audits and 100% test surge response. Many clients don’t know this—but during UL testing, fire resistance is one of the hardest metrics to pass. That’s why we don’t compromise on this, even when customizing products for ODM projects.

Conclusion

Every power strip includes housing, wiring, and safety layers that protect users and devices.